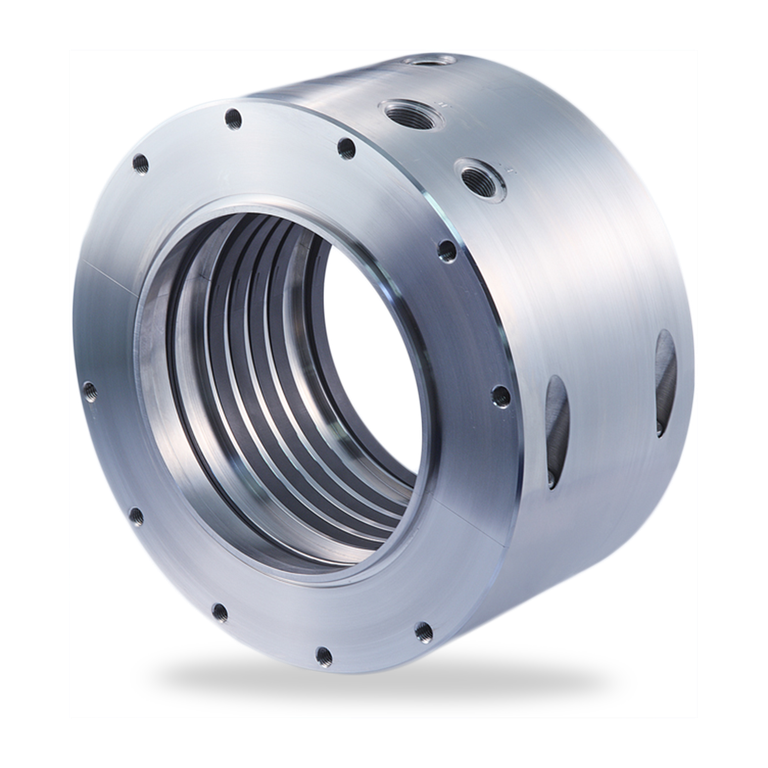

Espey Magna500+ the large seal for diameters from 500 mm

Espey Magna500+ the large seal for diameters from 500 mm

| Item | Description |

| 1 | Flat seal |

| 2 | Split housing design |

| 3 | Seal ring |

| 4 | Tension spring |

| 5 | Detent |

| 6 | Shaft sleeve |

Espey Magna500+ the large seal for diameters from 500 mm

Features

- Split housing design

- Segmented and self-adjusting seal rings

- Virtually maintenance- and wearfree

- Dry-running

- Suitable for horizontal and vertical use

Advantages

- Easy Dis-/Assembly due to split housing design

- Robust design

- Reduced leakage

- Reduced energy cost

- Reduced whistling noises

- Insensitive to aggressive media

Materials

Seal ring: Carbon, Inconel

Housing: 1.4571, 1.4878, 1.4832

Tension spring / detent: 1.4571

Other materials on request.

Dimensions on request.

Standards and approvals

- FDA

- ATEX

Recommended applications

- Dry and wet grinding

- Pyrolysis

- Biomass combustion

- Crystalizing

- Rotary kiln

- Mill

- Reactor

- Mixer, blender, dryer

- …

Similar products

Espey WD200

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap - low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free - sliding faces and machine consume no additional power

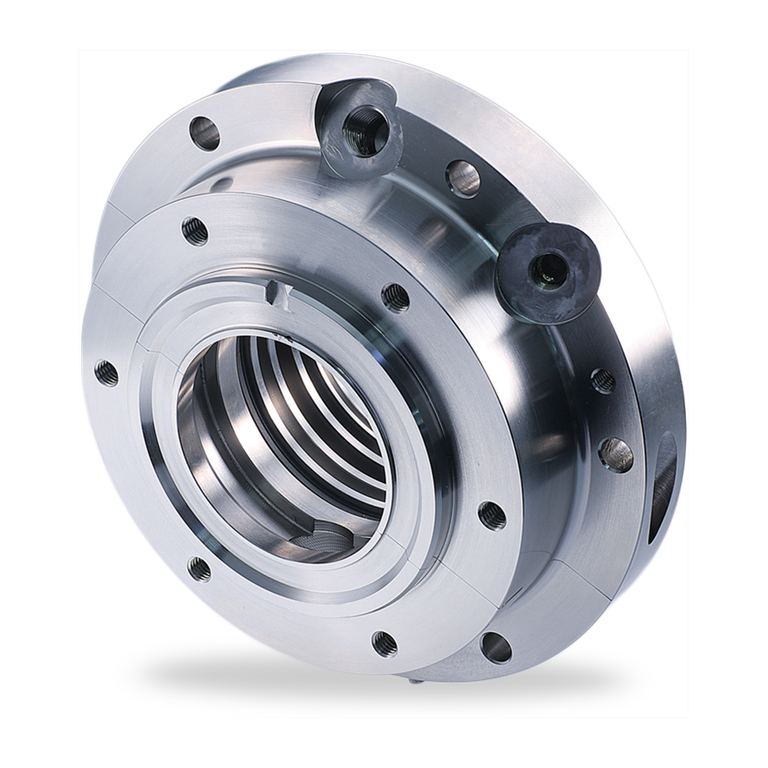

Espey WD200/500

- Multi-part seal rings, radially cut on process side, overlapped mortised with gas tight joints on atmosphere side (adjusting)

- Split housing design

- Lowest possible operation gap - lowest leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- Short axial installation length

- No sealing components mounted on the shaft and hence no additional shaft vibrations

Espey WD500

- Multi-part seal rings, overlapped mortised with gas tight Joints (adjusting)

- Split housing design

- Lowest possible operation gap - lowest leakage

- Dry-running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- Short axial installation length

- No sealing components mounted on the shaft and hence no additional shaft vibrations